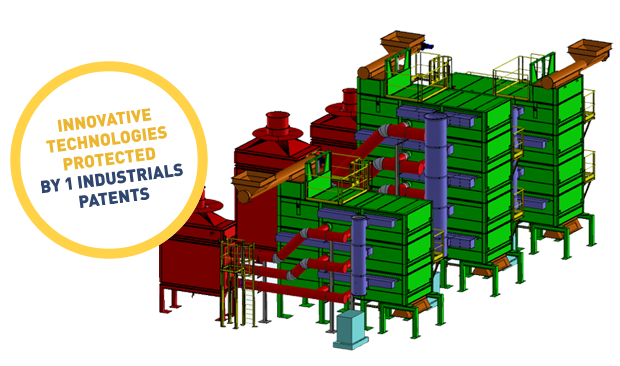

Our staged combustion technology, protected by 16 patents, makes it possible to produce green energy and sequester CO2 from poorly recycled waste. It is complemented by a range of dryers to recover very wet waste.

PRODUCING LOW-CARBON ENERGY

BY RECYCLING LOCAL WASTE

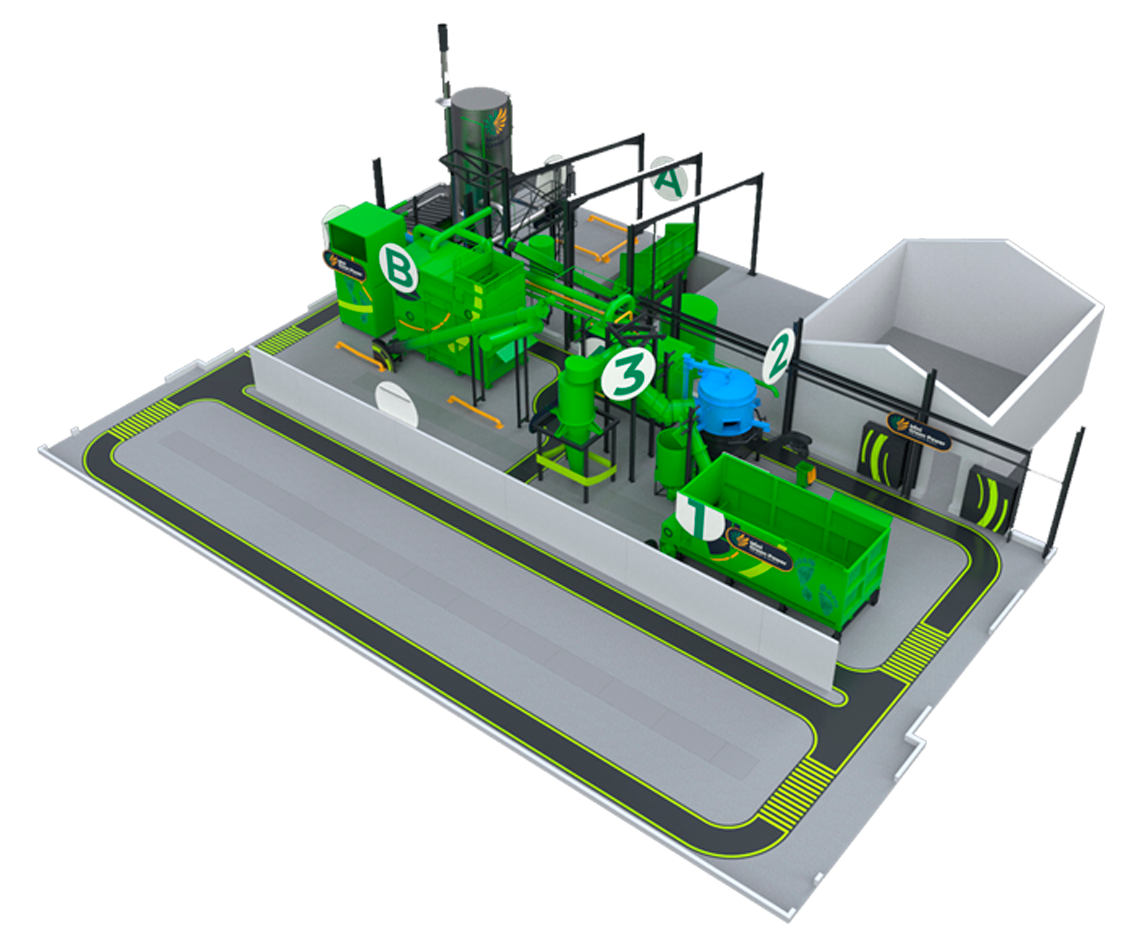

A SMALL SIZE

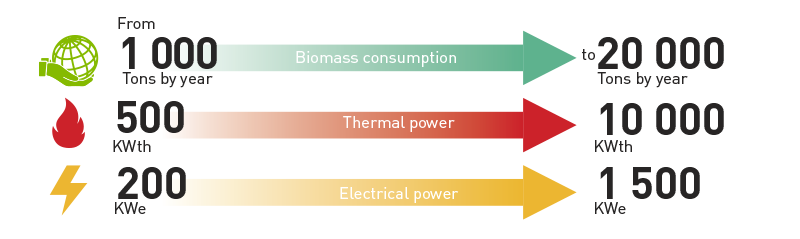

100 times smaller than traditional biomass power plants or incinerators, our mini green power plantsR are based on a power of 0.5 to 10 MW th and are fuelled by 1,000 to 20,000 tonnes of waste per year. This reduced power and the diversity of the waste accepted mean that the fuel can be sourced from a very small radius, in a short circuit.

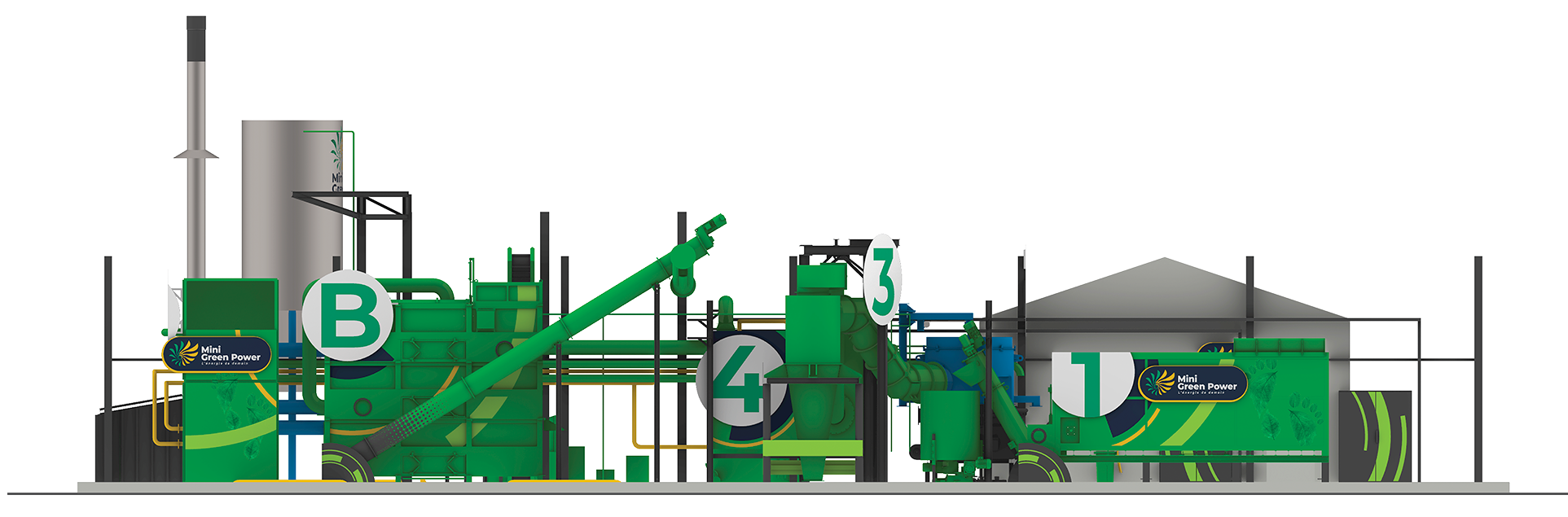

THE TECHNOLOGY

The recycled material (plant residues or RDF) is conveyed from the feed tank to the gasifier by conveyors. There it is heated to a high temperature in a low-oxygen atmosphere, where it undergoes three successive reactions: combustion, pyrogasification and post-combustion. This process, patented by Mini Green Power, produces hot air at over 1,000°C. This hot air is passed through a recovery boiler to heat a fluid used in the recovery process: superheated water, steam or thermal oil. The heat generated can then be used for heating, drying or industrial processes using steam. The heat can also be converted into cooling or electricity using specific modules.

Choosing Mini Green plant means adopting an environmentally-friendly solution that produces carbon-free energy while keeping your energy bill under control.

There are several factors that differentiate our technology from others on the market :

PRODUCTION

IN A SHORT CIRCUIT

THE BEST CO2 EMISSION RATES

The plants generate little dust, low NOx and low CO. High-temperature gas residence times ensure the elimination of volatile organic compounds and tars, minimising boiler clogging.

These emission rates are measured continuously using our automated control system.

FUELS AT LOW OR NEGATIVE PRICES

The cost of the fuel used (green waste, wood waste, RDF, etc.), which is often destined for landfill, is very low, sometimes even negative. The cost of the energy produced from this waste is therefore competitive, predictable and independent of fluctuations in energy market prices.

A WIDE RANGE OF RECOVERED WASTE

Mini green plant can process a wide range of plant residues (biomass, RDF, class B wood, shredded prunings, etc.), with a grain size (up to 150 mm) and moisture content (up to 55%) that are larger than conventional incinerators. This diversity of fuels accepted by the plant, combined with the choice of a technology based on a small power range, means that the fuel can be sourced from a very small radius. Energy is thus created in a short circuit, on your premises, from your own waste or waste produced locally.

MODULAR SOLUTIONS

By offering 3 sizes of power station (small, medium and large) to standardise the range, the cost price is reduced and financing is facilitated.

HIGH AUTOMATION AND A BIG DATA SOLUTION

Thanks to a control system developed in-house, our power plants are automated and backed up by Big Data solutions. They can be remotely controlled. As a result, operating costs are kept to a minimum and operations are continuously optimised.

THE TECHNOLOGY

To complete our offer, we propose to customers to couple the Mini Green Power Plant technology with a universal dryer capable of drying biomass and other products of agricultural origin. The dryers enable the desired drying to be achieved regardless of the material used, and guarantee the continuity of the deposit of wet green waste and RDF over three years.

FEATURES

Each drying line consists of several modules :

> One or more automated hoppers for the wet product

> A multi-stage dryer

> A heat exchanger to produce hot air from hot water

> An electrical cabinet and a control cabinet

The line requires several conveyors to transport the product between modules :

> A conveyor between the inlet silo(s) and the dryer

> A conveyor at the dryer outlet

PRODUCING LOW-CARBON ENERGY

BY RECYCLING LOCAL WASTE

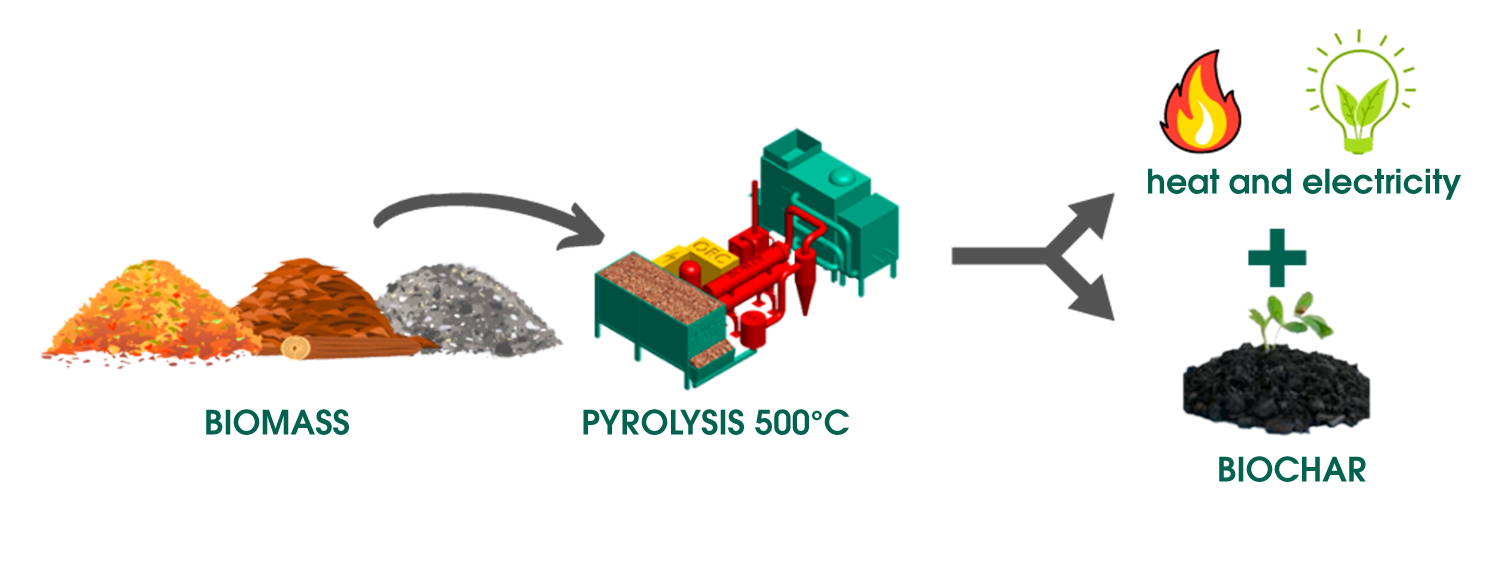

OUR TECHNOLOGY

Manufacture biochar while producing low-carbon energy.

The technology used in our mini green power stations enables biochar to be co-produced with energy when the fuel supply permits. Biochar is a veritable carbon sink. Produced from the pyrolysis of biomass, it is one of the most ecologically interesting ways of reducing carbon emissions! It is in this sense that it is promoted by the IPCC .

A WIDE RANGE OF OPPORTUNITIES

Activated carbon is a sought-after co-product for agricultural applications, as a replacement for fertilizers, and in the manufacture of concrete. It restores soil fertility and retains nutrients and water thanks to its porous structure.

In addition to its own commercial value, biochar is an effective means of sequestering CO2 when used for soil or incorporated into concrete.

BTP

> Complement for the manufacture of cement / concrete :

- stores carbon

- promotes the adhesion

of materials

AGRICULTURE

> Soil fertiliser

- stores carbon

- restores soil fertility

- retains nutrients and water

thanks to its porous structure

BREEDING

> Animal feed (cattle) :

Reduces methane production

from herds